Let’s take a peek behind the curtain at our manufacturing processes here at Induction Innovations. We pride ourselves on providing the highest quality, high-performance induction heaters on the market. One way we achieve that is by assembling the vast majority of our products right here in Elgin, Illinois.

To learn about the production process, we spoke with Operations Manager Paul Astrowski, who has been with Induction Innovations for over 13 years.

“In the beginning, Tom did all the manufacturing in his basement,” Astrowski recalled. “As the company grew, we hired contract manufacturers to build parts of the products.”

As the company expanded, a decision was made to bring more manufacturing in-house to improve the level of quality with each product and ensure that every item sent out was in perfect operating condition.

“Tom even started his own contract manufacturing company (Circuits by US),” which added another level of quality control to our products, Astrowski said.

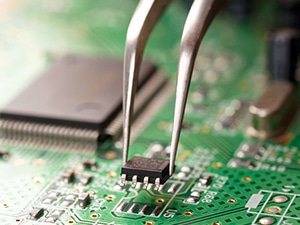

In-House Circuit Board Assembly

Today, Circuits by US, with 35 years of experience in manufacturing, starts the production process by assembling the circuit boards that power every Induction Innovations product. The boards are assembled at first by machine and later by hand as larger parts are added. The remainder of the assembly is also done by hand, in-house.

At each step of the assembly process, the products undergo various quality checks to guarantee that every aspect of the product works perfectly and looks just as good.

Save Time, Money and Aggravation with U.S. Made Induction Heating Tools

Whenever possible, we source materials in the U.S. such as our injection-molded housings and blow- molded cases. This is something many companies do overseas. While not every raw material is sourced in the U.S., we do as much as we can to ensure that as much as possible is made in America. This not only helps us control the quality of our products, but it is a source of pride to be able to say that our products are made and assembled in the U.S.A.

To learn more about how our U.S.-made induction heating tools can save you time, money and aggravation, give us a call or click on the link below.

Contact us to learn more about applications for our induction heat products