Quick. Safe.

Damage-free removal.

The Inductor is the professional’s choice handheld, flameless torch and leverages the power of Invisible Heat® to heat ferrous metals in seconds. Using high frequency magnetic fields, the Inductor releases corroded or frozen hardware and other metallic components from corrosion and thread lock compounds – all without the collateral damage normally associated with torches.

Using one of the included coils that can flex around corners a flame cannot, the Inductor heats a 3/4″ nut red hot in seconds.

Benefits

Inductor® Series Models

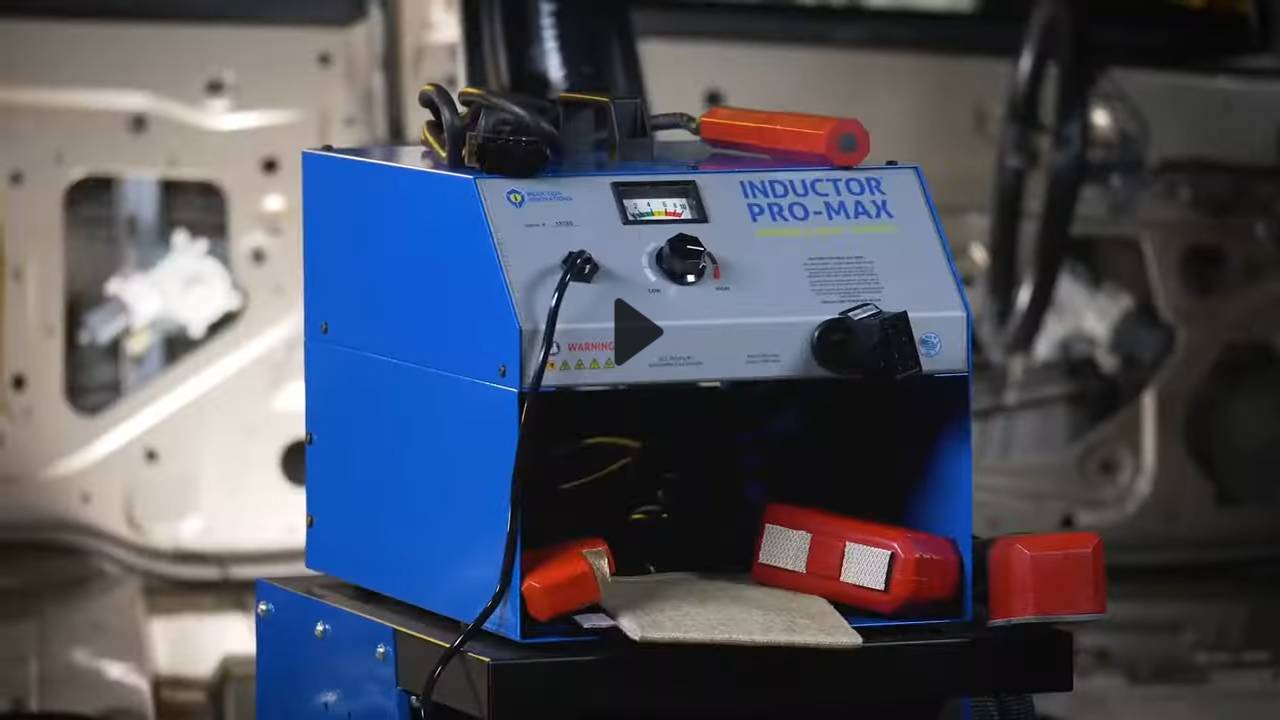

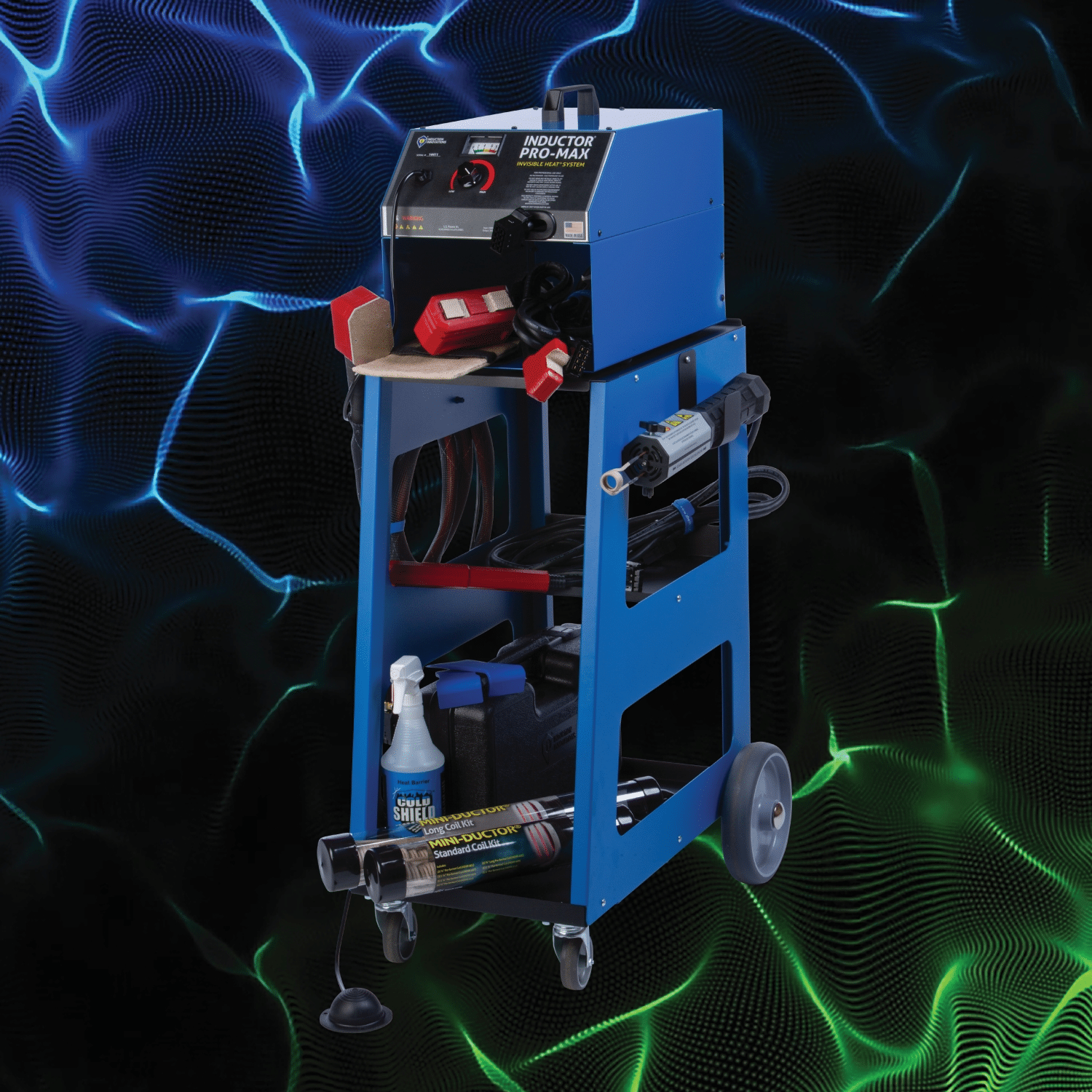

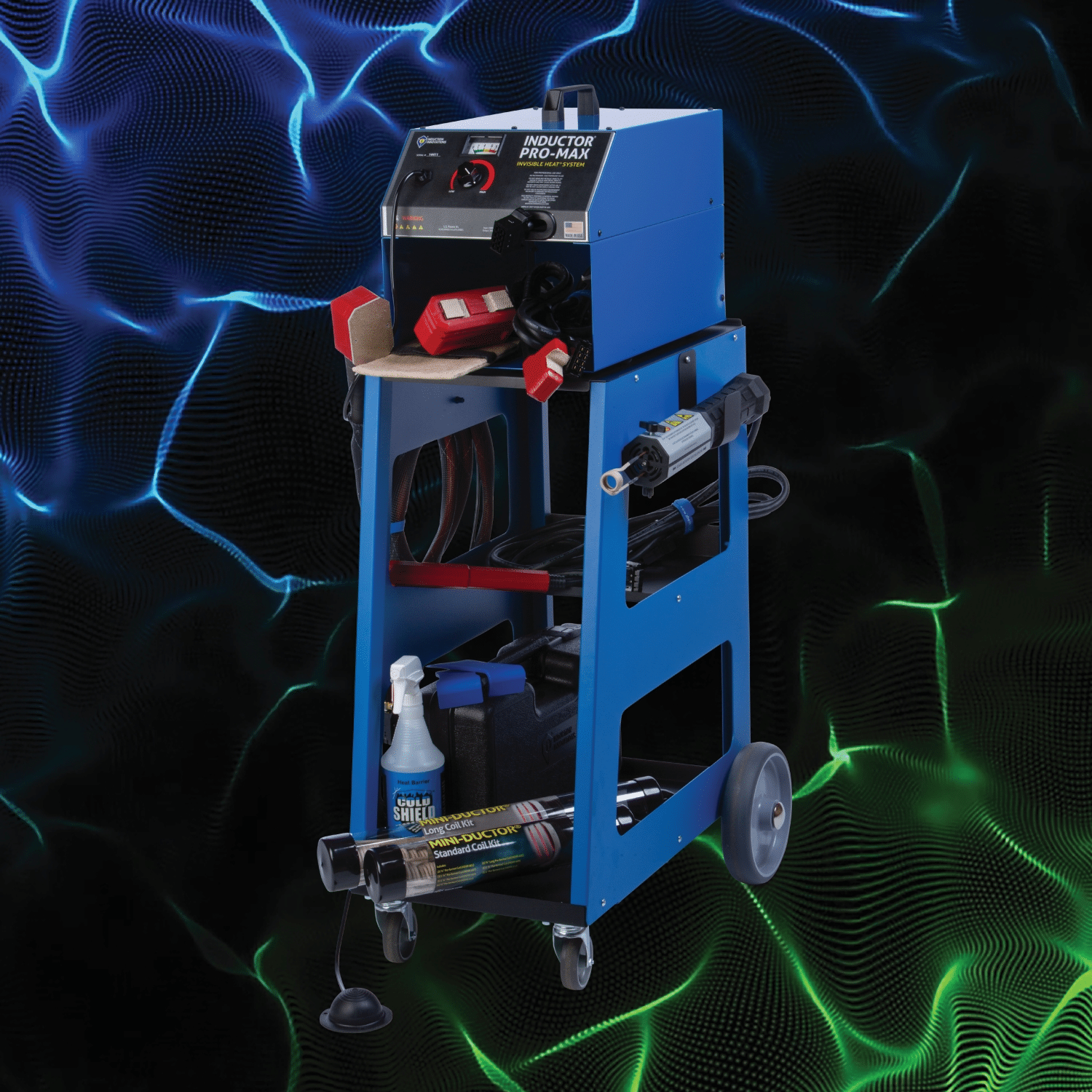

Inductor® Pro-Max Fully Loaded

(PM-200FL)

Offering so much more than simple precise flameless heat, the Pro-Max Fully Loaded is the auto pro’s new best friend, saving many hours in labor and adding positivity to the bottom line.

Inductor® Pro-Max

(PM-20000)

Remove ALL types of adhesives bonded to metal, release seized hardware from corrosion or thread lock compounds.

Inductor® Max

(IM-IND2011)

Quickly and easily remove vinyl graphics, moldings, autoglass, windshields, mechanical and suspension parts.

Inductor® Glass Blaster®

(GB-20311)

The Inductor Glass Blaster is perfect for removing windshields and other bonded auto glass, SMC panels, metal bond adhesives, undercoating, appliqués, and spray-on bedliners in a fraction of the time it takes using other tools.

International Inductors

Pro-Max CE Fully Loaded

Using high frequency magnetic fields, the Inductor Pro-Max CE Fully Loaded utilizes Invisible Heat® to easily remove parts bonded to metal.

Pro-Max CE

Using high frequency magnetic fields (induction heat), Pro-Max CE generates Invisible Heat® to remove all types of adhesives bonded to metal, release seized hardware from corrosion or thread lock compounds,

DEMOS AND VIDEOS

Learn From Our Experts

Everything you need to know in one place for you to explore.

How to Properly Use & Maintain Your Coils

Quick Tip Tuesday: How to Lock Coils Securely Into Place

Learn More About Our Company

Precise Heating With Induction Heat!