Induction Heating Tools for Body Shops

Induction heating tools are used in auto body shops for heat treating, soldering, preheating for welding, shrink fitting, glass removal, curing, de-bonding, and many other applications. Our tools provide the necessary precision when removing adhesives, body moldings, and auto glass.

Why Induction Heating is Essential for Body Shop Technicians

Induction heating is a method of heating electrically conductive materials (steel, aluminum, brass, copper, gold, platinum, etc.) and semiconducting materials (germanium and silicon). Induction heating is a contactless method of heating conductive and semi-conductive materials, and it is very fast and efficient. The Inductor® Pro-Max is a heavy-duty induction heating system that can be a workhorse in your auto body shop. The Inductor® series gives you a variety of attachments to meet many auto repair needs.

Fast, Safer Vehicle Repair

Our induction heater tools are ideal for:

Induction Heating vs.

The Torch: A Safer, Faster Solution

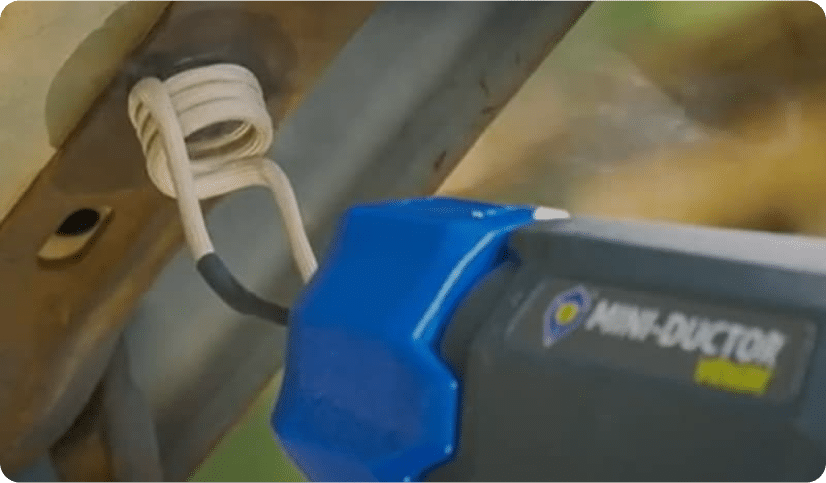

The Mini-Ductor’s ability to provide precise, localized heat makes it an invaluable tool for body shops, helping to speed up repairs and reduce the risk of damage to parts and surrounding areas. By reducing the time spent on repairs and minimizing the risk of damage, induction heating tools can help shops save on labor costs and avoid the expense of replacing damaged parts

Most Popular Body Shop Products

Eliminate the Torch,

Increase Safety

Torches are commonly used to remove the many rusted or otherwise seized nuts, bolts and bearings found on heavy duty equipment. However, using an open flame can be dangerous given build-ups of dust and other flammable material. Using an induction heater to replace most torch use is increasingly accepted by mechanics as a safer and faster way to repair heavy duty equipment, especially with the Mini-Ductor from Induction Innovations.