Induction Heating Tools for Automotive

The benefits of induction heating for automotive repairs include: precise and localized heating, which helps avoid collateral damage to surrounding parts, paint, or plastic components. This precision is particularly useful when working in tight spaces or near sensitive materials.

Why Induction Heating is Essential for Automotive Technicians

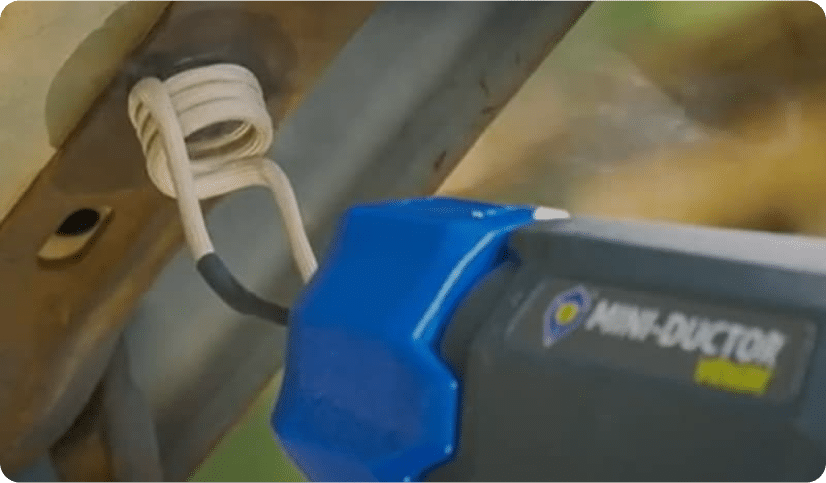

The Mini-Ductor is ideal for rusted and seized bolts, bearings and other ferrous metal parts and fasteners, especially in tight spots and areas where heat needs to be applied to metal but may be around fuel lines so it can cause secondary damage – with induction heat, you no longer have to shield fuel lines, which saves a lot of time and prevents damage.

Fast, Safe Part Removal

Our induction heater tools are ideal in removing:

Induction Heating vs.

The Torch: A Safer, Faster Solution

The Mini-Ductor’s ability to provide precise, localized heat makes it an invaluable tool for automotive shops, helping to speed up repairs and reduce the risk of damage to parts and surrounding areas. By reducing the time spent on repairs and minimizing the risk of damage, induction heating tools can help shops save on labor costs and avoid the expense of replacing damaged parts

Most Popular Automotive Products

Eliminate the Torch,

Increase Safety

Torches are commonly used to remove the many rusted or otherwise seized nuts, bolts and bearings found on heavy duty equipment. However, using an open flame can be dangerous given build-ups of dust and other flammable material. Using an induction heater to replace most torch use is increasingly accepted by mechanics as a safer and faster way to repair heavy duty equipment, especially with the Mini-Ductor from Induction Innovations.