The tool of choice for removing a rusted or seized part from corrosion or thread lock compounds is an important one for any technician. While some technicians select the torch, others are choosing induction heat. We know that torches are powerful however, they can be unreliable and unsafe to use. Here is why you should toss the torch and switch to an induction heating tool.

The tool of choice for removing a rusted or seized part from corrosion or thread lock compounds is an important one for any technician. While some technicians select the torch, others are choosing induction heat. We know that torches are powerful however, they can be unreliable and unsafe to use. Here is why you should toss the torch and switch to an induction heating tool.

First, How Does Induction Heat Work?

Induction heat is a flameless heat that is transferred from the unit to the application being heated via electromagnetic waves. The result is that the object being heated never comes into direct contact with any open flames and the coil itself does not get hot.

The coil is the transfer primary and the parts being heated become a short circuit secondary. When a metal part is placed in the induction coils and enters the magnetic field, circulating eddy currents are induced within the part. These eddy currents flow against the electrical resistivity of the metal, generating precise and localized heat without direct contact between part and coil.

Tools Designed to Solve Problems

Our induction heating tools are designed to solve problems such as removing stuck or corroded parts and adhesives in a faster, safer, and more precise way. Founder and President, Tom Gough, developed the first Inductor Series model in 2000. He was inspired to invent the tool after dealing with 28 years in collision repair and seeing the many time-consuming processes found in the vehicle and equipment repair industry.

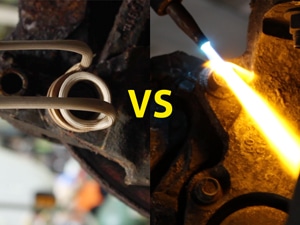

Benefits of Induction Heat Vs. Open Flames

Precise. Safe. Reliable.

The most important reason to make the switch to induction heat over an oxy-acetylene torch is that it is safer and more reliable. Torches can produce inconsistent results and uneven heating. Flames cover a larger surface area which, as a result, can cause more damage and catch plastics, wiring, fuel, or trim on fire.

Induction heat enhances workplace safety because of the precise, localized heat and no open flame. There is less potential to catch something on fire, damage the surrounding work areas or cause workplace injuries. When used properly by following the instruction manual, the results of induction heat are the same each time.

Increase Your Profitability

Induction heating tools allow users to salvage parts, some that may otherwise be discarded. When using a torch, consumables such as gas expenses can add up. You can reduce or eliminate those expenses by switching to induction heat. After purchasing the tool, additional costs may come from purchasing new coils. Our coils should last around 200 uses if taking the proper precautions. When they start to look worn or the insulation starts to tear, that is when you should replace them.

Save Time with the Mini-Ductor Series

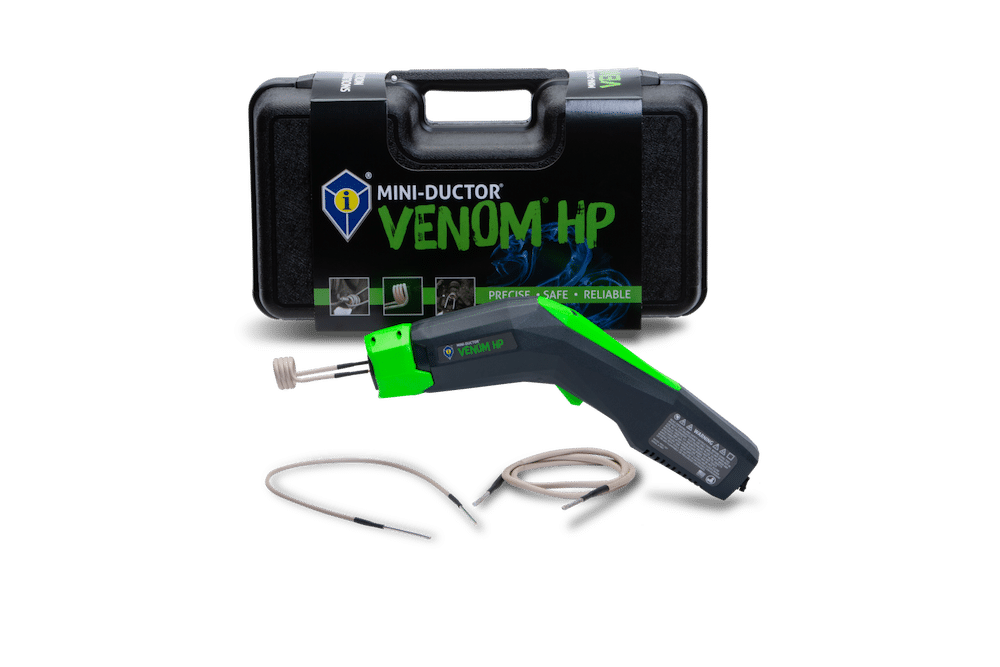

Our product lines run a wide range of power and portability, starting with the Mini-Ductor® product line. This series is the professional’s choice handheld flameless torch and the original handheld induction heater.

The Mini-Ductor Series saves time by reaching those tight-fitting areas where a flame cannot go. This line of heaters contains an inline design (Mini-Ductor II) or upgraded, angled pistol grip (Mini-Ductor Venom® and Venom HP) which helps technicians fit hard-to-reach areas. In addition to that, our flexible coils allow users to bend them in any shape to fit tight areas as well.

With induction heat, there is no need to cover or remove flammable parts nearby. Our tools allow you to work quickly and efficiently. For instance, a Mini-Ductor tool can turn ¾” nuts red hot in just a matter of seconds!

Mini-Ductor Applications Include:

- Lug Nut Removal

- Exhaust Manifold Bolts

- O2 Sensors

- Graphics and Decals

- Struts

- Seatbelt Bolts

- Inline Connectors

- 100’s more!

Contact Us Today!

To learn more about induction heat and how our products can save you time and money, reach out to us via phone at 877-688-9633 or email at [email protected].

Follow us on social media: