The Occupational Safety and Health Administration (OSHA) is a regulatory agency tasked with ensuring safe and healthful working conditions for private and public sector workers as a subset of the United States Department of Labor. The organization has set strict regulations regarding the use of open flame torches within the workplace to ensure safe working conditions. These regulations also include standards for welding, oxygen-acetylene storage, and other safety measures that must be followed.

The Occupational Safety and Health Administration (OSHA) is a regulatory agency tasked with ensuring safe and healthful working conditions for private and public sector workers as a subset of the United States Department of Labor. The organization has set strict regulations regarding the use of open flame torches within the workplace to ensure safe working conditions. These regulations also include standards for welding, oxygen-acetylene storage, and other safety measures that must be followed.

Because of these critical requirements (which may lead to expensive upgrades), professional shops need safe, effective alternatives to remove and repair seized parts, spray-on bed liners, auto glass, and more. We’ve outlined several reasons why OSHA requirements and other induction heating benefits have led professional technicians to switch from traditional flame torches and welders to modern induction heating products.

OSHA Open Flame Regulations

It’s entirely feasible that because of the many OSHA standards for fire prevention and protection, torch shops should consider transitioning away from the open flame. Some reasons include the following:

1. Fire Hazards & Guards

OSHA notes that when objects that require cutting or welding cannot be moved, all other fire hazardous material should be moved to a safe place. This includes the use of guards for confinement when fire hazards can’t be relocated. Without these precautions, cutting and welding cannot take place.

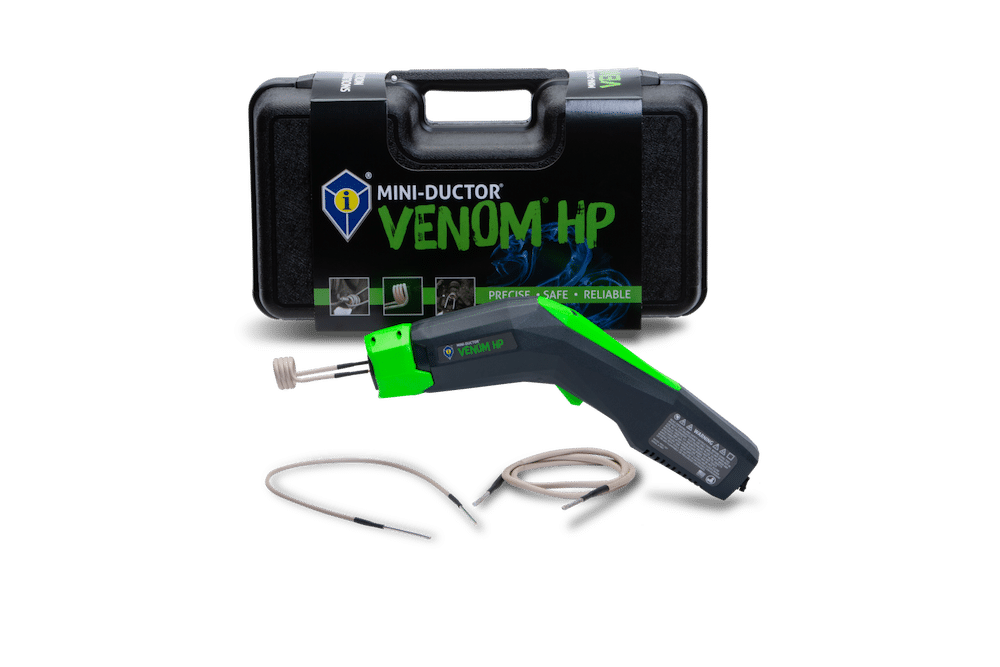

In manufacturing settings, logistics and the purchase of specialized guards can be costly and time-consuming. Our Mini-Ductor® Induction Heater Tool Models help to curb these issues. They are handheld flameless torch solutions that can fit around hard-to-reach areas, and because they operate without a flame, there is less need for guarding hard-to-move or immovable objects.

2. Combustible Material

OSHA requires that no open flames or other sources of ignition be operated within 50 feet of flammable liquids. Additionally, precautions must be taken to enclose any floor openings or cracks to ensure they aren’t exposed to sparks. Oxygen-acetylene torches and welders can ignite any combustible material within their vicinities.

An induction heater, when used properly, is a much safer alternative. Products like the Inductor® Pro-Max Fully Loaded (PM-200FL) produce precise, accurate heat for applications such as heating bearings, O2 sensors, and more, without the risk (or the need for expensive fuel and other consumables). Induction heat places heat where you need it when you want it.

3. Prohibited Areas

There are many industrial areas where OSHA requirements do not allow open flame operation.

Including:

- Near explosive or flammable gas, vapor, liquid, and dust mixtures

- Near materials that could ignite

- In any area that hasn’t been established with procedures for cutting and welding and deemed “fire safe.”

4. Fire Watchers & Related Resource Needs

Often, OSHA regulations require “fire watchers” on staff whenever welding or cutting operations are performed and where combustible materials or wall/floor openings are present. These individuals must be trained and equipped with fire extinguishers. Fire watchers must also watch the operational area for at least 30 minutes after a job is complete in case of smoldering.

5. Safety Equipment

The use of an oxygen-acetylene torch requires personal safety equipment such as helmets, hand shields, goggles, and any safeguards when working off the ground, including railings and welding cables. Induction heating safety is less intensive. However, users will still need to take all necessary precautions when handling the tool. Breach of insulators or electrical failure should be a concern as they may generate a spark.

Lower Insurance Premiums

While each company that transitions to induction heating solutions has a unique situation, we have found that our customers save on average 10%-30% less on their insurance premiums than users of traditional torches. These savings can be attributed to the fact that induction heating tools provide a high safety value.

Learn more about the case against oxygen-acetylene torches and welders and discover why many industries have switched to induction heating alternatives.

Contact Us:

The team at Induction Innovations is happy to answer any questions you may have about induction heating, our tools, and the importance of using safe, effective products for critical applications. Reach us via phone at 877-688-9633 or email at [email protected].

Follow us on social media: Facebook • Instagram • LinkedIn • TikTok • YouTube